Burnishing Leather

What is leather burnishing?

Burnishing our leather edges is going to slick the edges of our leather project. Just look at the edges of a holster, knife sheath or a high-end handbag. We will notice gorgeous, rounded edges that are slicked, and many times have an edge paint or edge coat added. A leather burnisher is an easy tool to purchase and will add a professional level to the edges of our leather project.

Tools used for burnishing leather edges

(Leather Edge Treatment) :

Edge Groover

The leather edge groover can be used to drop in a groove line for accent or decoration on our leather projects. We can use a deeper groove line to guide our stitching chisel or to stitch leather and it acts as protective groove for the stitches. Edge groovers are also used when we want to create a fold line.

Leather Edge Beveler

A leather edge beveler will let us knock off the hard top edge on both front and back of our leather project. The sharp metal blade on the leather bevel tool lets us slide it at an angle and cut the square edge corners from our leather project.

Leather Burnisher

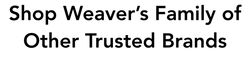

The leather burnishing tool sometimes called a leather slicker, is used to slick or burnish the leather edges on our project.

Finishes to slick leather edges :

There are many leather edge treatment recipes that a person can use to slick their leather and they work great. Here are three options.

Water

We can use water to slick the leather edges of your project. It works great.

Beeswax

Beeswax works nicely for slicking leather edges.

Tokonole

Tokonole Burnishing Gum is a water based alternative to gum tragacanth, and our team can attest that it works beautifully to achieve smooth, glossy edges.

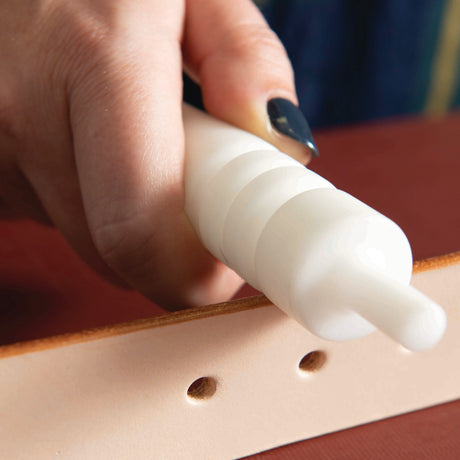

Saddle Soap

Saddle soap, simply apply to leather, let dry and polish with a soft cloth to achieve a beautiful luster.

Gum Tragacanth

Chuck Dorsett's favorite thing to use for slicking his leather edges is Gum Tragacanth. Chuck realizes the benefits of using Gum Tragacanth is durability, ease of use and the quickest edge treatment to slick our leather edges.

How to finish leather edges

- When adding the finish that we choose to slick our leather edges, we have to be careful not to drop it on the face of our leather project. So, the goal is not to drop gum tragacanth, oil, wax or water on the face of the leather while coating the edges because that will give us problems when we proceed to the top coating process of our leather project.

- Secondly, we don't want to use so much edge finish that the edges become mushy. We need a bit of body left in the leather. It does not take long to understand how much edge finish is needed.

- After we've applied our edge finish, let's take our slicker and find the groove in the slicker that best fits our leather's thickness. Run the slicker back and forth on the edge of the leather and watch as the leather edge picks up a glossy look.

- Next, keep going back and forth for a couple of seconds.

- Now, stop and go up to the next larger size groove and use that to fine tune and polish the edge.

- We should be able to see and feel the smooth, high gloss, rounded edge of our leather project. It should feel good to the touch and look good to the eye.

- For an even glossier edge use a high grit sand paper on your leather edge prior to burnishing.

Tools for burnishing leather (Slicking leather)

While there are many items that you can use to burnish leather including a deer antler and canvas, we will talk about some great tools that do a terrific job.

Chuck Dorsett has two favorite leather burnishers:

Exotic Wood Leather Slicker: 65-2961

Plastic Leather Slicker: 65-2962.

Both tools are made just for burnishing and have a shank that allows us to put the slicker tool in our drill press or drill. It offers three grooves that will cover three weights of leather. Because the weights of leather vary, we could use a couple of different weights in each groove. There is a tapered edge and rounded edges all the way down the tool. The tool allows us to get a good slick on the smallest oblong.